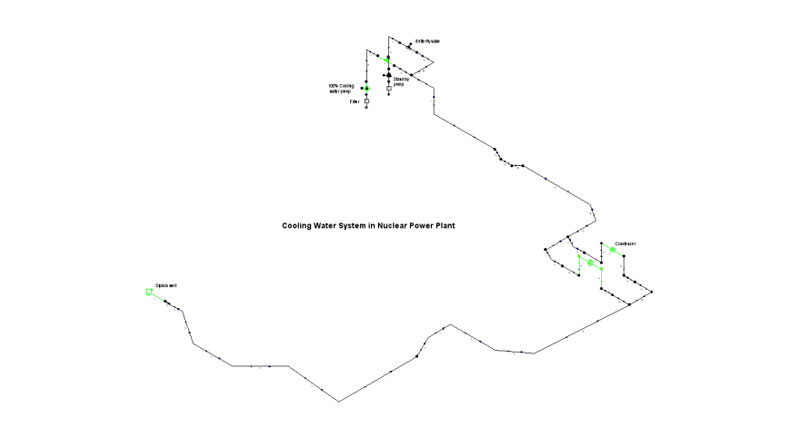

Water Hammer in Nuclear Plant Cooling Water System

Background

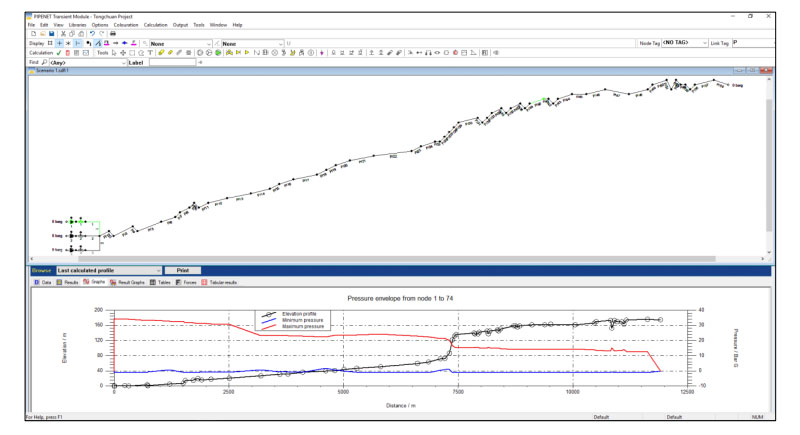

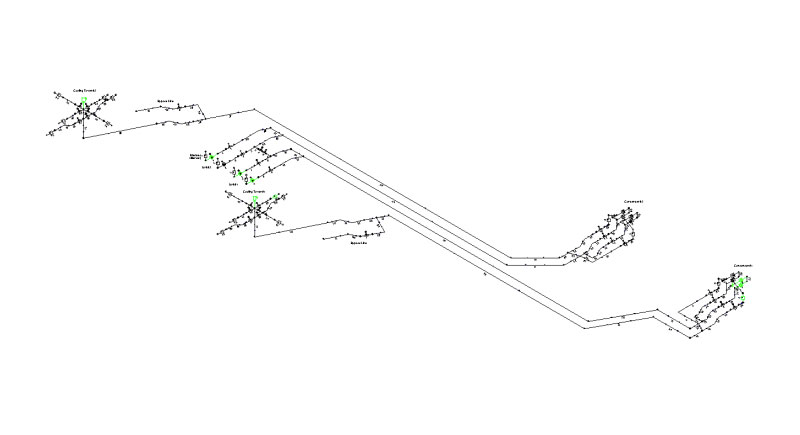

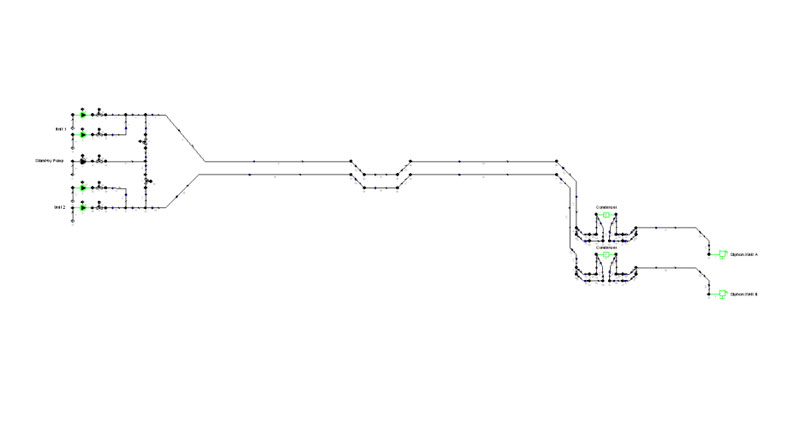

This study was performed for the designers of a nuclear power plant in China. The plant incorporates a seawater direct cooling system, using carbon steel and concrete pipes. Water is pumped from the sea, and after passing through a butterfly valve is routed to the condensers and finally back to the sea via a siphon well.

The customer wished to estimate the pressure surges caused by pump trip and start up, and evaluate measures to control water hammer including the use of vacuum breakers and optimization of the siphon well.